MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 1 of 909

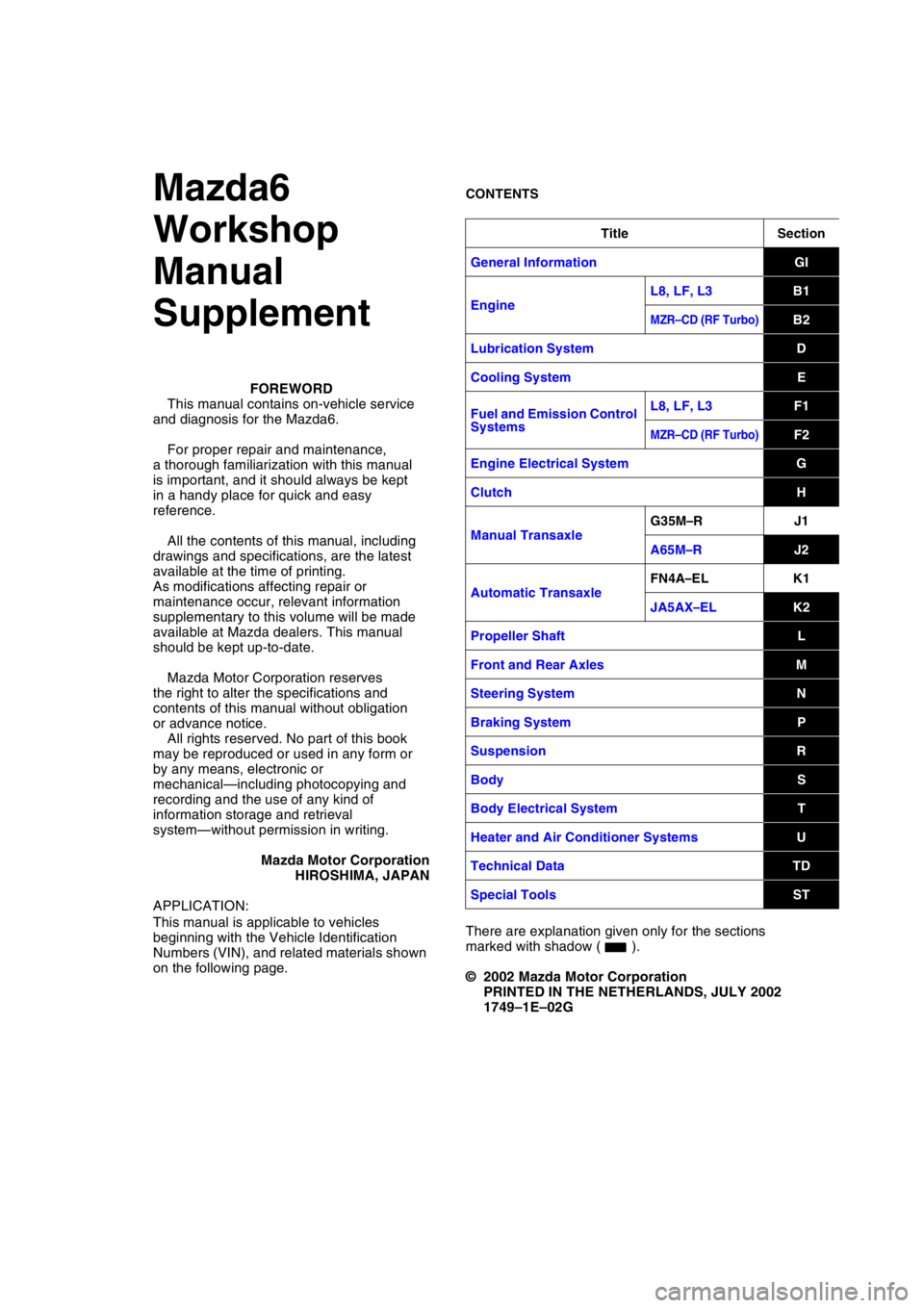

CONTENTSMazda6

Workshop

Manual

Supplement

FOREWORD

This manual contains on-vehicle service

and diagnosis for the Mazda6.

For proper repair and maintenance,

a thorough familiarization with this manual

is important, and it should always be kept

in a handy place for quick and easy

reference.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be made

available at Mazda dealers. This manual

should be kept up-to-date.

Mazda Motor Corporation reserves

the right to alter the specifications and

contents of this manual without obligation

or advance notice.

All rights reserved. No part of this book

may be reproduced or used in any form or

by any means, electronic or

mechanical—including photocopying and

recording and the use of any kind of

information storage and retrieval

system—without permission in writing.

Mazda Motor Corporation

HIROSHIMA, JAPAN

APPLICATION:

This manual is applicable to vehicles

beginning with the Vehicle Identification

Numbers (VIN), and related materials shown

on the following page.There are explanation given only for the sections

marked with shadow ( ).

© 2002 Mazda Motor Corporation

PRINTED IN THE NETHERLANDS, JULY 2002

1749–1E–02G

Title Section

General Information

GI

EngineL8, LF, L3

B1

MZR–CD (RF Turbo)B2

Lubrication System

D

Cooling System

E

Fuel and Emission Control

SystemsL8, LF, L3

F1

MZR–CD (RF Turbo)F2

Engine Electrical System

G

Clutch

H

Manual TransaxleG35M

–RJ1

A65M

–RJ2

Automatic TransaxleFN4A

–ELK1

JA5AX

–ELK2

Propeller Shaft

L

Front and Rear Axles

M

Steering System

N

Braking System

P

Suspension

R

Body

S

Body Electrical System

T

Heater and Air Conditioner Systems

U

Technical Data

TD

Special Tools

ST

Page 2 of 909

VEHICLE IDENTIFICATION NUMBERS (VIN)

U.K. specs.

JMZ GG12R20# 100001—

JMZ GG12T20# 100001—

JMZ GG14R20# 100001—

JMZ GG14T20# 100001—

JMZ GY19320# 100001—

JMZ GY19820# 100001—

JMZ GY19F20# 100001—

JMZ GY19F50# 100001—

JMZ GY19R20# 100001—

JMZ GY19T20# 100001—

JMZ GY89370# 100001—

European (L.H.D.) specs.

JMZ GG12R2✻# 100001—

JMZ GG12T2✻# 100001—

JMZ GG14R2✻# 100001—

JMZ GG14T2✻# 100001—JMZ GY1932✻# 100001—

JMZ GY1982✻# 100001—

JMZ GY19F2✻# 100001—

JMZ GY19F5✻# 100001—

JMZ GY19R2✻# 100001—

JMZ GY19T2✻# 100001—

JMZ GY8937✻# 100001—

GCC specs.

JM7 GG32F✻✻# 100001—

JM7 GG42F✻✻# 100001—

JM7 GG34F✻✻# 100001—

JM7 GG44F✻✻# 100001—

JM7 GY49F✻✻# 100001—

JM7 GY39F✻✻# 100001—

JM7 GY49F✻0# 100001—

JM7 GY39F✻0# 100001—

RELATED MATERIALS

Mazda6 Training Manual

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 3359–1*–02C

Mazda6 Workshop Manual

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 1730–1*–02C

Engine Workshop Manual L8, LF, L3 . . . . . . . . . . . . . . 1731–1*–02C

Engine Workshop Manual MZR–CD (RF Turbo) . . . . . 1744–1E–02D

Manual Transaxle Workshop Manual G35M–R . . . . . . 1732–1*–02C

Manual Transaxle Workshop Manual A65M–R . . . . . . 1739–1E–02D

Automatic Transaxle Workshop Manual FN4A–EL . . . 1623–10–98E

Automatic Transaxle Workshop Manual

Supplement FN4A–EL . . . . . . . . . . . . . . . . . . . . . . . . . 1746–1*–02C

Automatic Transaxle Workshop Manual JA5A–EL . . . 1738–1E–02D

Automatic Transaxle Workshop Manual

Supplement JA5AX–EL . . . . . . . . . . . . . . . . . . . . . . . . 1765–1*–02H

Mazda6 Wiring Diagram

(European (L.H.D.), GCC specs.) . . . . . . . . . . . . . . . . 5558–1*–02G

Mazda6 Wiring Diagram

(U.K. specs.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5559–1*–02G

Mazda6 Bodyshop Manual

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 3360–1*–02C

Mazda6 Bodyshop Manual Supplement

(European (L.H.D. U.K.), GCC specs.) . . . . . . . . . . . . 3368–1*–02I

EOBD Training Manual

(European (L.H.D. U.K.), Australian specs.) . . . . . . . 3345–1*–00B

* : Indicates the printing location

E: Europe

0: Japan

Page 3 of 909

WARNING

Servicing a vehicle can be dangerous. If you have not received

service-related training, the risks of injury, property damage, and

failure of servicing increase. The recommended servicing procedures

for the vehicle in this workshop manual were developed with

Mazda-trained technicians in mind. This manual may be useful to

non-Mazda trained technicians, but a technician with our

service-related training and experience will be at less risk when

performing service operations. However, all users of this manual are

expected to at least know general safety procedures.

This manual contains "Warnings" and "Cautions" applicable to risks

not normally encountered in a general technician's experience.

They should be followed to reduce the risk of injury and the risk that

improper service or repair may damage the vehicle or render it unsafe.

It is also important to understand that the "Warnings" and "Cautions"

are not exhaustive. It is impossible to warn of all the hazardous

consequences that might result from failure to follow the procedures.

The procedures recommended and described in this manual are

effective methods of performing service and repair. Some require tools

specifically designed for a specific purpose. Persons using procedures

and tools which are not recommended by Mazda Motor Corporation

must satisfy themselves thoroughly that neither personal safety nor

safety of the vehicle will be jeopardized.

The contents of this manual, including drawings and specifications, are

the latest available at the time of printing, and

Mazda Motor Corporation

reserves the right to change the vehicle designs and alter the contents

of this manual without notice and without incurring obligation.

Parts should be replaced with genuine Mazda replacement parts or

with parts which match the quality of genuine Mazda replacement

parts. Persons using replacement parts of lesser quality than that of

genuine Mazda replacement parts must satisfy themselves thoroughly

that neither personal safety nor safety of the vehicle will be

jeopardized.

Mazda Motor Corporation is not responsible for any problems which

may arise from the use of this manual. The cause of such problems

includes but is not limited to insufficient service-related training, use of

improper tools, use of replacement parts of lesser quality than that of

genuine Mazda replacement parts, or not being aware of any revision

of this manual.

Page 4 of 909

GI–1

GIGIGENERAL INFORMATION

HOW TO USE THIS MANUAL............................. GI-2

RANGE OF TOPICS .......................................... GI-2

VIN CODE............................................................. GI-3

VIN CODE .......................................................... GI-3

FUNDAMENTAL PROCEDURES........................ GI-4

DYNAMOMETER ............................................... GI-4

NEW STANDARDS.............................................. GI-5

NEW STANDARDS TABLE ............................... GI-5

ABBREVIATIONS................................................ GI-7

ABBREVIATIONS TABLE .................................. GI-7

SCHEDULED MAINTENANCE............................ GI-8

SCHEDULED MAINTENANCE TABLE ............. GI-8

Page 5 of 909

GI–2

HOW TO USE THIS MANUAL

RANGE OF TOPICSA6E201000001206•This manual indicates only changes/additions, as it is supplemental to the related materials. Therefore it may

not contain the necessary reference service procedures to perform the service indicated in this manual.

End Of Sie

HOW TO USE THIS MANUAL

Page 6 of 909

VIN CODE

GI–3

GIVIN CODEA6E200800021201European (L.H.D. U.K.) specs.GCC specs.End Of Sie

VIN CODE

Serial No.

0=Hiroshima

2=5MT For Europe(U.K.): Dummy

For Europe(L.H.D.): Dummy

For Israel: Model year0

3 to 9

3=2003

3=2.3L (L3)

8=1.8L (L8)

F=2.0L (LF)

R=MZR-CD(RF-Turbo)-Hi

T=MZR-CD(RF-Turbo)-Low5=4EAT

7=5EAT

8=4WD

1=2WD

GG=MAZDA6 (4SD, 5HB)

GY=MAZDA6 (WAGON)

JMZ=Europe(L.H.D. U.K.)2=4SD

4=5HB

9=WAGON 1=Hofu Plant

Engine typeWorld manufacturer identification

Body style

Remarks

Vehicle type

Transmission

A6E2021T101

J M 7 G Y 3 9 F * 3 # 1 2 3 4 5 6

Serial No.

0= Hiroshima

1= Hofu

0 to 9, X

F= 2.0L (LF)

9= WAGON 4= 5HB 2= 4SD

JM7= General (L.H.D.) 3= Without side air bag

4= With side air bag

GY= MAZDA6 (WAGON) GG= MAZDA6 (4SD, 5HB) Plant

For Saudi: Model year

For Model year: Dummy

Body style Engine typeCheck digit3

0 - 9

Restraint system

Vehicle type

World manufacturer identification

A6E2010T102

Page 7 of 909

GI–4

FUNDAMENTAL PROCEDURES

DYNAMOMETERA6E2014000042174WD testing/servicing

•Brake tester

Caution

•

To ensure the stability of the drag force of the viscous coupling always perform a brake test after

using the dynamometer or speed meter tester.

Note

•If there is a great amount of brake drag, it is probably due to the viscosity of the viscous coupling or the

center differential (RBC). To remove the influence of the coupling, jack up all four wheels of the vehicle

and verify that each wheel can be rotated freely by hand.

•Chassis dynamometer/speed meter tester

Caution

•

The vehicle may sway or surge forward when on the dynamometer. To prevent possible vehicle

movement, firmly secure it in place using steel retainers (chain, wire or similar) attached to the

front and rear towing hooks or to the tie down hooks.

•

Do not pop the clutch.

•

Do not accelerate suddenly.

Note

•The dynamometer/speed meter tester has two setting modes: propeller shaft removed mode and free

roller mode. After placing the vehicle on the tester and setting the wheels on the free rollers, start the

engine. For MTX vehicles, set the shift lever into second gear and gently, at low idle speed, release the

clutch pedal. For ATX vehicles, set the selector lever to D range, and slowly accelerate.

End Of Sie

FUNDAMENTAL PROCEDURES

Page 8 of 909

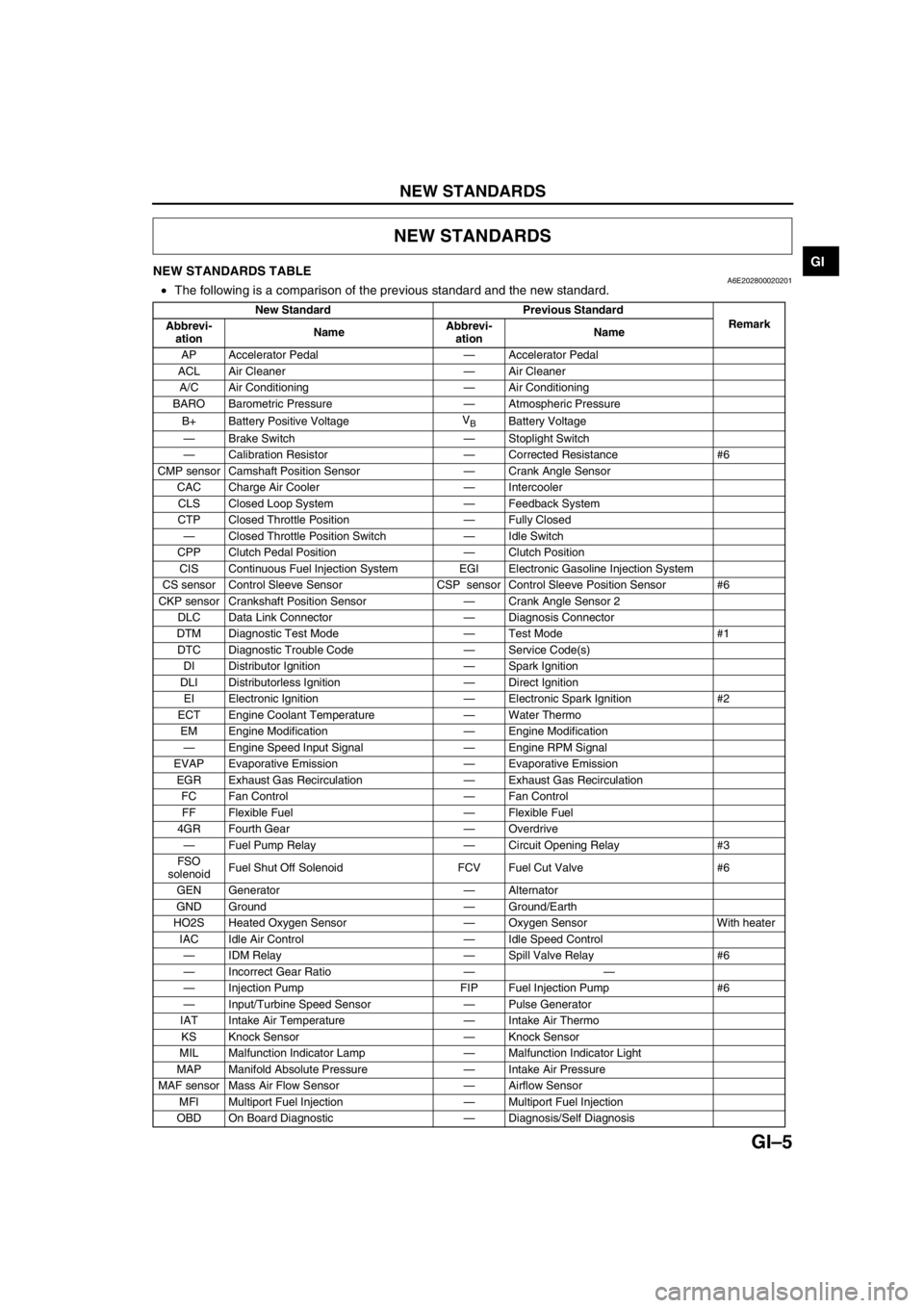

NEW STANDARDS

GI–5

GINEW STANDARDS TABLEA6E202800020201•The following is a comparison of the previous standard and the new standard.

NEW STANDARDS

New Standard Previous Standard

Remark

Abbrevi-

ationNameAbbrevi-

ationName

AP Accelerator Pedal—Accelerator Pedal

ACL Air Cleaner—Air Cleaner

A/C Air Conditioning—Air Conditioning

BARO Barometric Pressure—Atmospheric Pressure

B+ Battery Positive VoltageV

BBattery Voltage

—Brake Switch—Stoplight Switch

—Calibration Resistor—Corrected Resistance #6

CMP sensor Camshaft Position Sensor—Crank Angle Sensor

CAC Charge Air Cooler—Intercooler

CLS Closed Loop System—Feedback System

CTP Closed Throttle Position—Fully Closed

—Closed Throttle Position Switch—Idle Switch

CPP Clutch Pedal Position—Clutch Position

CIS Continuous Fuel Injection System EGI Electronic Gasoline Injection System

CS sensor Control Sleeve Sensor CSP sensor Control Sleeve Position Sensor #6

CKP sensor Crankshaft Position Sensor—Crank Angle Sensor 2

DLC Data Link Connector—Diagnosis Connector

DTM Diagnostic Test Mode—Test Mode #1

DTC Diagnostic Trouble Code—Service Code(s)

DI Distributor Ignition—Spark Ignition

DLI Distributorless Ignition—Direct Ignition

EI Electronic Ignition—Electronic Spark Ignition #2

ECT Engine Coolant Temperature—Water Thermo

EM Engine Modification—Engine Modification

—Engine Speed Input Signal—Engine RPM Signal

EVAP Evaporative Emission—Evaporative Emission

EGR Exhaust Gas Recirculation—Exhaust Gas Recirculation

FC Fan Control—Fan Control

FF Flexible Fuel—Flexible Fuel

4GR Fourth Gear—Overdrive

—Fuel Pump Relay—Circuit Opening Relay #3

FSO

solenoidFuel Shut Off Solenoid FCV Fuel Cut Valve #6

GEN Generator—Alternator

GND Ground—Ground/Earth

HO2S Heated Oxygen Sensor—Oxygen Sensor With heater

IAC Idle Air Control—Idle Speed Control

—IDM Relay—Spill Valve Relay #6

—Incorrect Gear Ratio——

—Injection Pump FIP Fuel Injection Pump #6

—Input/Turbine Speed Sensor—Pulse Generator

IAT Intake Air Temperature—Intake Air Thermo

KS Knock Sensor—Knock Sensor

MIL Malfunction Indicator Lamp—Malfunction Indicator Light

MAP Manifold Absolute Pressure—Intake Air Pressure

MAF sensor Mass Air Flow Sensor—Airflow Sensor

MFI Multiport Fuel Injection—Multiport Fuel Injection

OBD On Board Diagnostic—Diagnosis/Self Diagnosis

Page 9 of 909

GI–6

NEW STANDARDS

#1 : Diagnostic trouble codes depend on the diagnostic test mode.

#2 : Controlled by the PCM

#3 : In some models, there is a fuel pump relay that controls pump speed. That relay is now called the fuel pump

relay (speed).

#4 : Device that controls engine and powertrain

#5 : Directly connected to exhaust manifold

#6 : Part name of diesel engine

End Of Sie

OL Open Loop—Open Loop

—Output Speed Sensor—Vehicle Speed Sensor 1

OC Oxidation Catalytic Converter—Catalytic Converter

O2S Oxygen Sensor—Oxygen Sensor

PNP Park/Neutral Position—Park/Neutral Range

—PCM Control Relay—Main Relay #6

PSP Power Steering Pressure—Power Steering Pressure

PCM Powertrain Control Module ECU Engine Control Unit #4

—Pressure Control Solenoid—Line Pressure Solenoid Valve

PAIR Pulsed Secondary Air Injection—Secondary Air Injection SystemPulsed

injection

—Pump Speed Sensor—NE Sensor #6

AIR Secondary Air Injection—Secondary Air Injection SystemInjection

with air

pump

SAPV Secondary Air Pulse Valve—Reed Valve

SFI Sequential Multiport Fuel Injection—Sequential Fuel Injection

—Shift Solenoid A—1–2 Shift Solenoid Valve

—Shift A Solenoid Valve

—Shift Solenoid B—2–3 Shift Solenoid Valve

—Shift B Solenoid Valve

—Shift Solenoid C—3–4 Shift Solenoid Valve

3GR Third Gear—3rd Gear

TWC Three Way Catalytic Converter—Catalytic Converter

TB Throttle Body—Throttle Body

TP sensor Throttle Position Sensor—Throttle Sensor

TCV Timer Control Valve TCV Timing Control Valve #6

TCC Torque Converter Clutch—Lockup Position

TCMTransmission (Transaxle) Control

Module—EC-AT Control Unit

—Transmission (Transaxle) Fluid

Temperature Sensor—ATF Thermosensor

TR Transmission (Transaxle) Range—Inhibitor Position

TC Turbocharger—Turbocharger

VSS Vehicle Speed Sensor—Vehicle Speed Sensor

VR Voltage Regulator—IC Regulator

VAF sensor Volume Air Flow Sensor —Airflow Meter

WU-TWCWarm Up Three Way Catalytic

Converter—Catalytic Converter #5

WOT Wide Open Throttle—Fully Open New Standard Previous Standard

Remark

Abbrevi-

ationNameAbbrevi-

ationName

Page 10 of 909

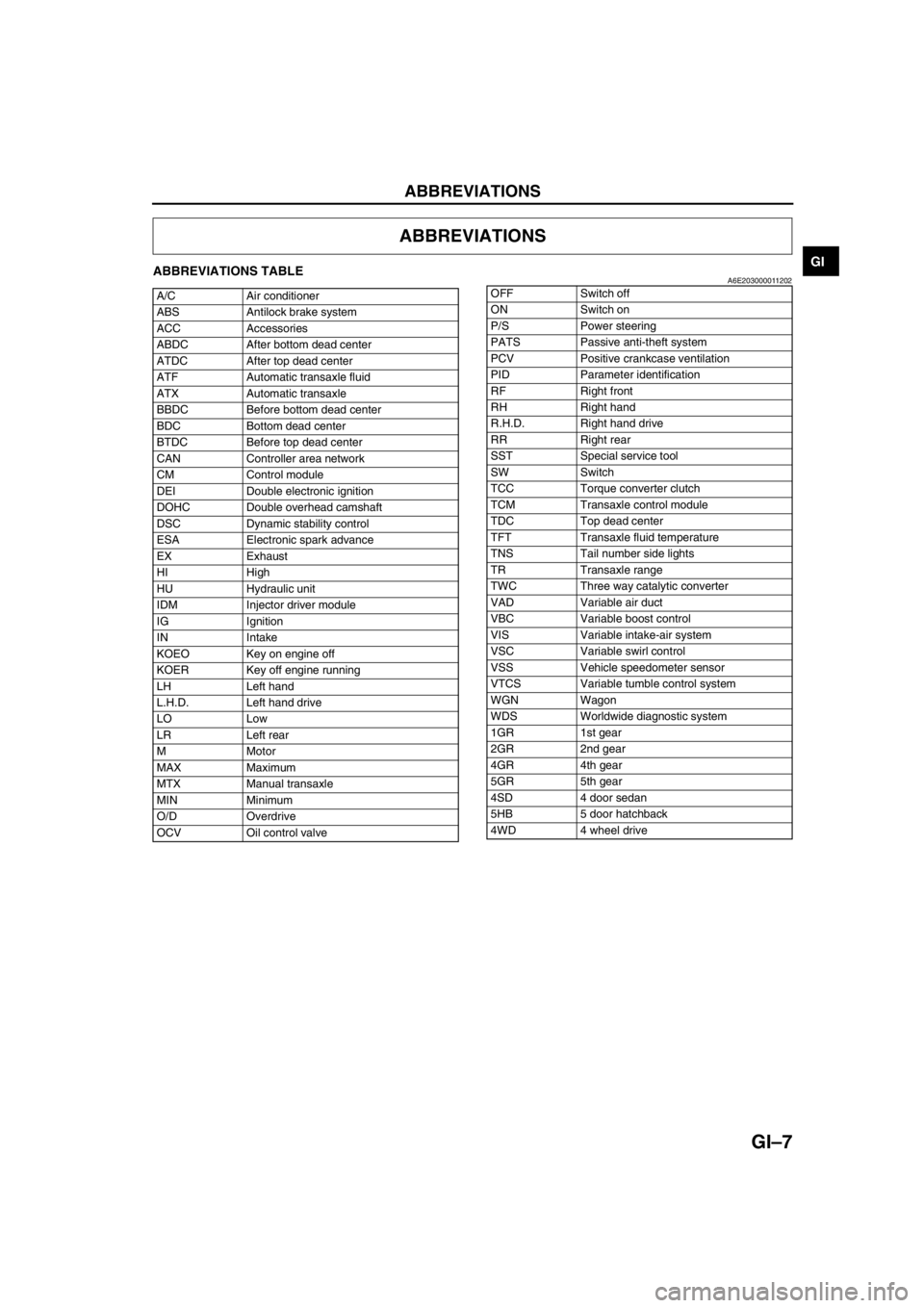

ABBREVIATIONS

GI–7

GIABBREVIATIONS TABLEA6E203000011202

End Of Sie

ABBREVIATIONS

A/C Air conditioner

ABS Antilock brake system

ACC Accessories

ABDC After bottom dead center

ATDC After top dead center

ATF Automatic transaxle fluid

ATX Automatic transaxle

BBDC Before bottom dead center

BDC Bottom dead center

BTDC Before top dead center

CAN Controller area network

CM Control module

DEI Double electronic ignition

DOHC Double overhead camshaft

DSC Dynamic stability control

ESA Electronic spark advance

EX Exhaust

HI High

HU Hydraulic unit

IDM Injector driver module

IG Ignition

IN Intake

KOEO Key on engine off

KOER Key off engine running

LH Left hand

L.H.D. Left hand drive

LO Low

LR Left rear

M Motor

MAX Maximum

MTX Manual transaxle

MIN Minimum

O/D Overdrive

OCV Oil control valveOFF Switch off

ON Switch on

P/S Power steering

PATS Passive anti-theft system

PCV Positive crankcase ventilation

PID Parameter identification

RF Right front

RH Right hand

R.H.D. Right hand drive

RR Right rear

SST Special service tool

SW Switch

TCC Torque converter clutch

TCM Transaxle control module

TDC Top dead center

TFT Transaxle fluid temperature

TNS Tail number side lights

TR Transaxle range

TWC Three way catalytic converter

VAD Variable air duct

VBC Variable boost control

VIS Variable intake-air system

VSC Variable swirl control

VSS Vehicle speedometer sensor

VTCS Variable tumble control system

WGN Wagon

WDS Worldwide diagnostic system

1GR 1st gear

2GR 2nd gear

4GR 4th gear

5GR 5th gear

4SD 4 door sedan

5HB 5 door hatchback

4WD 4 wheel drive